|

|

Post by Haines Garage on Mar 29, 2015 15:27:14 GMT -5

Got a new Exide Heavy Duty Battery.

This is what the starter dies now .

Any ideas? This is Killing Me!!!

I pulled the starter. It spins and the drive gear pops out and goes back.

|

|

|

|

Post by Haines Garage on Mar 29, 2015 16:46:52 GMT -5

Next piece of the puzzle.

The Hawk called me and told me to try this.

Thoughts?

|

|

|

|

Post by Mr. Wizzard on Mar 29, 2015 16:48:53 GMT -5

I would pull the starter and check the Bendix. It sounds like the spring behind the plate the helps push the gear forward might have broken. OR, you may just need to grease between the Bendix shaft and the gear. Maybe it is sticking a little so it cant get forward fast enough to engage. Attachments:

|

|

|

|

Post by Mr. Wizzard on Mar 29, 2015 16:50:53 GMT -5

Even if it's not that specific spring, it sounds like a broken Bendix spring to me. Something else I'm thinking of since I have my armature on my desk to look at...if the Bendix unit wasn't tightened down correctly, it may have shifted toward the rear so that it's not forward far enough to mesh with the ring gear. I'm throwing just about everything out I can think of.

-Mark

|

|

|

|

Post by Haines Garage on Mar 29, 2015 17:37:27 GMT -5

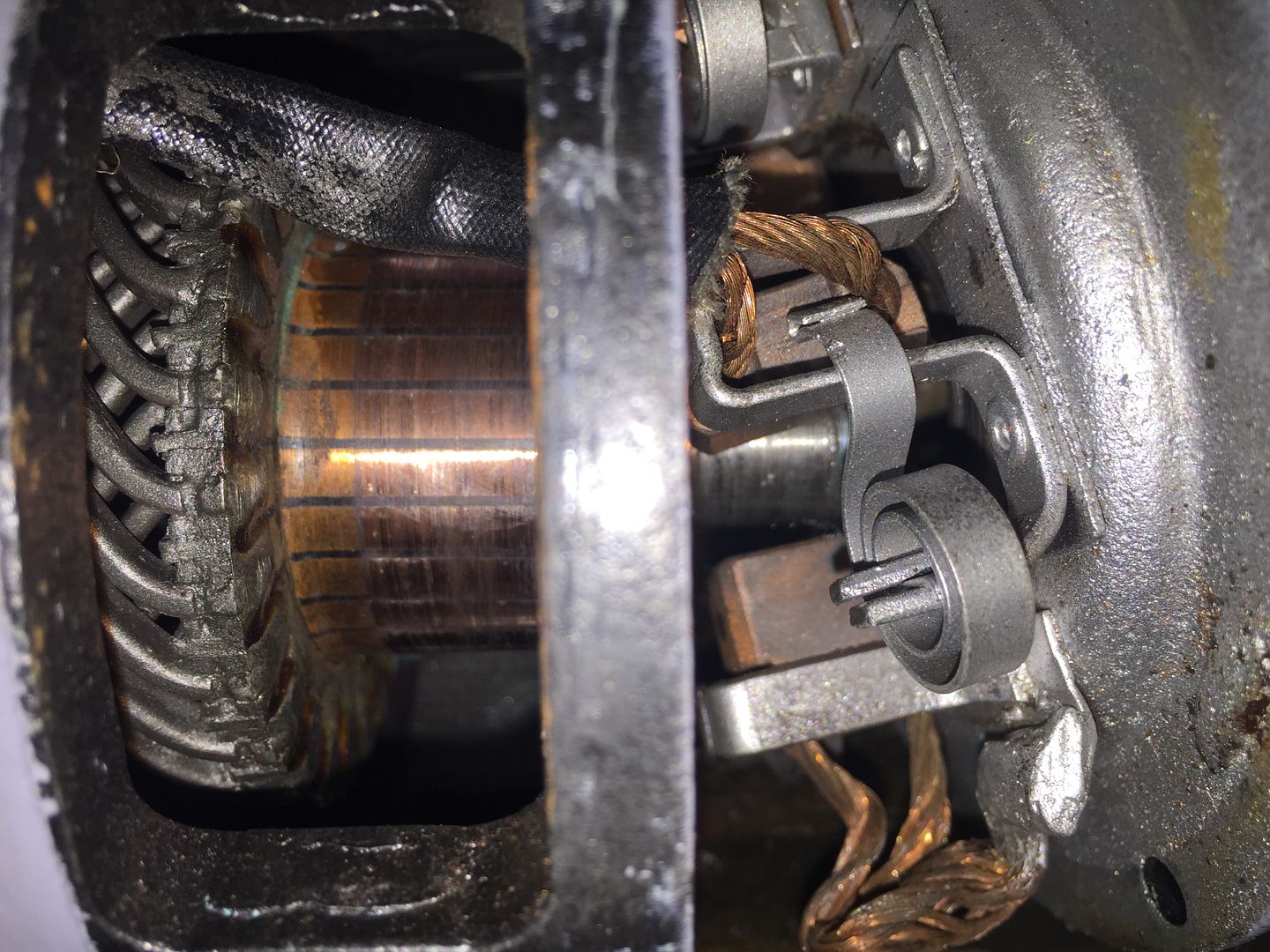

How do I disassemble? I already took the rear cover off, brushes look ok. What do you think?  |

|

|

|

Post by Haines Garage on Mar 29, 2015 17:38:26 GMT -5

The copper are looks wore to me, but I really have no clue about these.

Something tells me I am about to learn the hard way.

|

|

|

|

Post by Mr. Wizzard on Mar 29, 2015 17:39:19 GMT -5

It's not the brushes. That motor is spinning like crazy. Look where the starter bottlenecks. There are 4 5/16ths bolts. take those out and the starter housing splits in half and you can pull the armature out. I was going to say be careful so you don't have to fight the brushes to reseat them, but you've already pulled em hahaha.

|

|

|

|

Post by Mr. Wizzard on Mar 29, 2015 17:41:06 GMT -5

The copper are looks wore to me, but I really have no clue about these. Something tells me I am about to learn the hard way. So long as the carbon dividers are still there it should be alright. That's what keeps it from shorting itself out. you can clean it with sandpaper if you want since you've already got it out but I don't think that's an issue. Doesn't look like anything was actually done by the shop though. |

|

|

|

Post by Hawk on Mar 29, 2015 18:08:33 GMT -5

Well, there you have it.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 29, 2015 18:27:51 GMT -5

It kinda hard to judge by the pic, but the brushes and springs look pretty good if not new.

Btw, don't put grease on the bendix, it's supposed to be dry. All grease does is catch dirt and clutch debris and gums up.

|

|

|

|

Post by Mr. Wizzard on Mar 29, 2015 18:33:23 GMT -5

It kinda hard to judge by the pic, but the brushes and springs look pretty good if not new. Btw, don't put grease on the bendix, it's supposed to be dry. All grease does is catch dirt and clutch debris and gums up. Good catch. I meant dry graphite spray, and only if it's really sticking. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 29, 2015 18:54:44 GMT -5

HG...check your flatfender inbox. Detard sent those to me back in December.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 29, 2015 19:32:18 GMT -5

The copper part is the Armature. It definitely needs cleaning. The Bendix is in the nose of the starter behind the small gear. If you are going to have it rebuilt, make sure the new Bendix gear has the same number of teeth as the old one.

|

|

|

|

Post by Haines Garage on Mar 29, 2015 19:33:44 GMT -5

Bubba Haines Responds To this BS!!!!

|

|

|

|

Post by Mr. Wizzard on Mar 29, 2015 19:39:50 GMT -5

The copper part is the Armature. It definitely needs cleaning. The Bendix is in the nose of the starter behind the small gear. If you are going to have it rebuilt, make sure the new Bendix gear has the same number of teeth as the old one. The armature is the the large part with the "windings". The copper part where the brushes contact is the communicator. I could definitely use a cleaning but it doesn't seem to be causing any issues with the motor turning. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 30, 2015 3:42:33 GMT -5

HG is the communicator. Do you mean commutator?

|

|

|

|

Post by Mr. Wizzard on Mar 30, 2015 9:04:34 GMT -5

Yes lol. I guess my phones vocabulary isn't mechanically inclined.

|

|

|

|

|

|

Post by athawk11 on Mar 30, 2015 9:44:19 GMT -5

HG,

Your starter is an MZ4113. If the Bendix spring has broken, ($23.00) this is a pretty easy fix. If the cast parts on the Bendix have broken...also an easy fix, just a bit more expensive ($63.00). Both issues can be solved by calling Walcks for a new part.

In your re-builders defense, these parts do break. And there is no way to tell if and when they will break. If I were rebuilding a starter, I would replace these parts. If I were re-furbishing the starter, I probably wouldn't replace the parts. How much did you spend? Did he itemize what he did to the starter?

The other thing to check is the bushing inside the bell housing. If sloppy, this can contribute to the starters' demise. I've recently discovered that mine needs to be replaced.

Tim

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 30, 2015 20:33:55 GMT -5

X2 on the bell housing bushing X2 on the spring breaking, even more so with a tight, fresh engine X2 on purchasing a new bending drive  |

|

|

|

Post by Haines Garage on Mar 30, 2015 21:18:49 GMT -5

I am sure all these things are important,

Watch the spin test video again. There is no way I should be able to hold that with one hand!!!

I was told lucky I didn't wear it in my face.

It has no Torque!!!

Why is still out to the jury. I have an idea.

Look back at the open case pic!

This was a BS rebuild.

It will be proven...stay tuned.

|

|

|

|

Post by Haines Garage on Mar 30, 2015 21:23:36 GMT -5

This video..

|

|

|

|

Post by Mr. Wizzard on Mar 30, 2015 21:26:19 GMT -5

I am sure all these things are important, Watch the spin test video again. There is no way I should be able to hold that with one hand!!! I was told lucky I didn't wear it in my face. It has no Torque!!! Why is still out to the jury. I have an idea. Look back at the open case pic! This was a BS rebuild. It will be proven...stay tuned. I would have like to have seen the rest of the internals haha. Did you get a glance at what your field coils looked like? That "rebuild" job you got looked like something you could have done in 20 minutes for probably less than $20. I'm also wondering if they bothered to replace either of the bushings in the starter, if they tested the armature and commutator connections for any breaks, cleaned the contact side of the armature stud the battery cable connects to, a whole bunch of stuff. Honestly, the most difficult part is getting the frackin' screws to break loose that hold the backing plates in that hold field coils. I've been working on that for days.....  |

|

|

|

Post by Mr. Wizzard on Mar 30, 2015 21:28:57 GMT -5

It almost looks like they didn't sand the brushes so they fully contact the commutator, either. I wonder if that could be part of the reason your torque seems so low.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 30, 2015 21:57:36 GMT -5

If they trued up the communtator in a armature lathe, they didn't undercut the mica neither....but I've been told some shops don't do that anymore....

|

|