|

|

Post by zooke581 on May 1, 2016 14:01:22 GMT -5

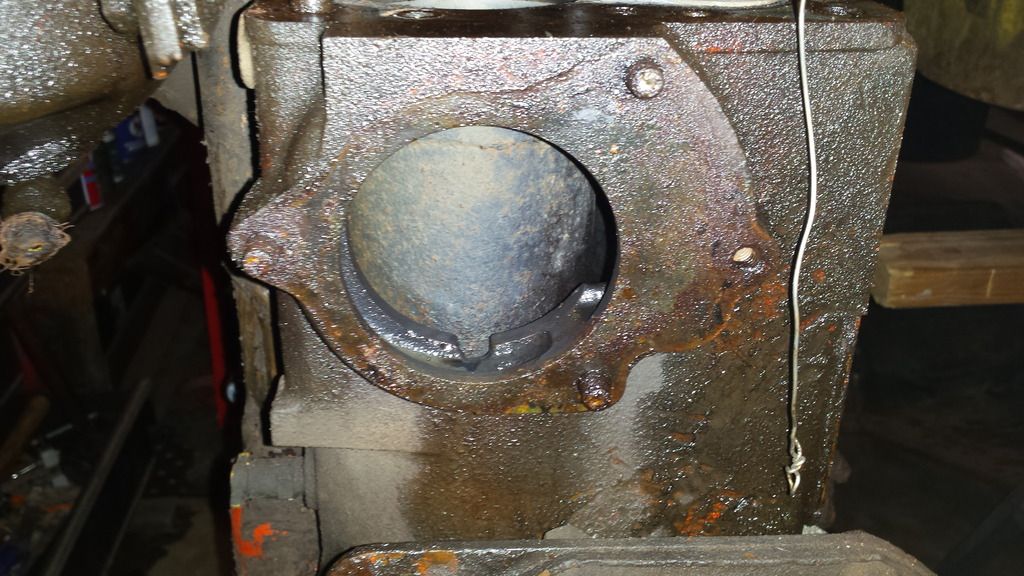

Just noticed that #3 is going as well. Still had good compression at 90 psi but...not for much longer by the looks of this.  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on May 1, 2016 17:28:40 GMT -5

Looks like the engine is coming out. New pistons and a checkup. At least a rod isn't through the side. I wonder if someone didn't turn the tops down on those pistons after decking the block too much. The whole upper ring groove is going. wow. Keep us informed. Oilly

|

|

|

|

Post by zooke581 on May 1, 2016 18:08:36 GMT -5

It's a Supersonic motor. Never taken apart since built from the factory. Standard pistons. I don't know if they have special pistons, I do know the head is milled for more compression. I am going to rebuild this one later down the line after my GPW motor for Arty.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on May 1, 2016 18:30:44 GMT -5

Supersonic head has less squish area which raises compression. Other than that, I think the block castings were also different. Arty will be cool. I'm with you on that one! You have lots on your plate now my friend. Oilly

|

|

|

|

Post by zooke581 on May 1, 2016 20:20:28 GMT -5

Have to put Arty to the side for a few. Need to do a heart transplant in the next week on Short Round. The new heart for Short Round. Out of my first Jeep buy in Feb 2013. The start of my affliction. The motor ran great. I did trade the head (early non ribbed) for a GPW head that will go on Arty. I have a ribbed head in my stash from an earlier trade in 2013.  The pistons are 060 over and look good. Engine just had some leaks so I have ordered a Fel Pro gasket set from Advanced Auto. only $62.39 and no shipping. I plan on doing all the gaskets and the rear main while it is out. Need to get the transplant done before the 21st. Short Round has many appointments this time of year.  |

|

|

|

Post by zooke581 on May 1, 2016 20:22:05 GMT -5

Can anyone loan me a valve spring compressor? I plan to clean up the valves and re lap them in.

|

|

|

|

Post by Haines Garage on May 1, 2016 21:20:48 GMT -5

Can anyone loan me a valve spring compressor? I plan to clean up the valves and re lap them in. Nope. Strip that engine down, and take it to the machinist. When you do this, I will come see you for a weekend in VA. I will bring my valve spring compressor. How about that? |

|

|

|

Post by zooke581 on May 1, 2016 21:44:47 GMT -5

This is a quick fix. I need it up and running in less than two weeks. This motor ran great. I just did no use it as I got the motor running that is in Short Round and used it as it was already in the frame. I do plan to mic everything on this motor to be safe.

|

|

|

|

Post by jeffwho on May 2, 2016 11:23:32 GMT -5

This is a quick fix. I need it up and running in less than two weeks. This motor ran great. I just did no use it as I got the motor running that is in Short Round and used it as it was already in the frame. I do plan to mic everything on this motor to be safe. Good luck my man. I tried the same quick fix and had to eat Schiller's crow pie. SOOO BITTER! LOL Anyway, I'm pulling for you, Lucille doesn't have the schedule Short Round does for sure. If no one else will send one, I will send my valve spring compressor - just let me know. He's got to get out and make the rounds! |

|

|

|

Post by zooke581 on May 2, 2016 11:26:29 GMT -5

Jeff, the 46 motor was a good runner and was rebuilt. So I am going to reseal afyer checking specs a quick repaint and then transplant.

I'll pm the address.

|

|

|

|

Post by jeffwho on May 2, 2016 11:46:57 GMT -5

roger that, happy to help ya

|

|

|

|

Post by zooke581 on May 2, 2016 19:53:13 GMT -5

Well got the 46 engine on the stand. Not easy. Do not have a hoist. So...put it on the motorcycle small lift. Short by 12 inches extended. Had to do a fulcrum effect by lifting each opposite side of the stand with the engine on it and adding a two by four each time till it was close. Then I had to take off the front wheel on the stand to get it under the motorcycle lift. All the while it is balancing vicariously. Then as a few two by fours were oh so...called the Wife to help hold the stand while I pushed the engine towards it and into the pivot. Done. Whew!!!!!

Drained the oil and worked on getting off the exhaust and intake manifold, two broken bolts on the outside ends of the exhaust. Hopefully not to hard to fix. Only other broken bolts are the three for the water pump. All head bolts came out okay.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on May 3, 2016 5:20:39 GMT -5

I've got an engine sitting in my garage with a snapped water pump bolt. Please detail your endeavors!

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on May 3, 2016 6:08:34 GMT -5

Sounds like a cheap 3/4 ton chain hoist and some extra long boards up in the rafters are needed. The cable come alongs are a recipe for disaster. Dropped an engine once with one. Never again. I'm not a fan of drilling any of those snapped off bolts. Get comfortable and take your time. New bits and mystic metal mover. Try and hit it dead center on the first bit. Do not break a easy out off in one. The tactic of heating and melting wax into the threads etc. has never worked for me. Heating before you snap off the bolt has worked for me, but once snapped, it's drill time. Be careful with the manifold bolts. You can drill too far and hit a cylinder. Machine shops have a method of taking them out, but I've never seen how. Might be worth asking. Oilly

|

|

|

|

Post by zooke581 on May 3, 2016 12:45:20 GMT -5

Harbor Freight has the 1 ton cherry picker for $178. Guess I'll get that. Going to need it a few times.

|

|

|

|

Post by zooke581 on May 3, 2016 20:13:54 GMT -5

This is what I had last night, broken bolts in the water pump housing and two out bolts broken on the exhaust.  The two outer exhaust bolts are longer. The front one broke off flush and the back one just the head part.  |

|

|

|

Post by zooke581 on May 3, 2016 20:18:24 GMT -5

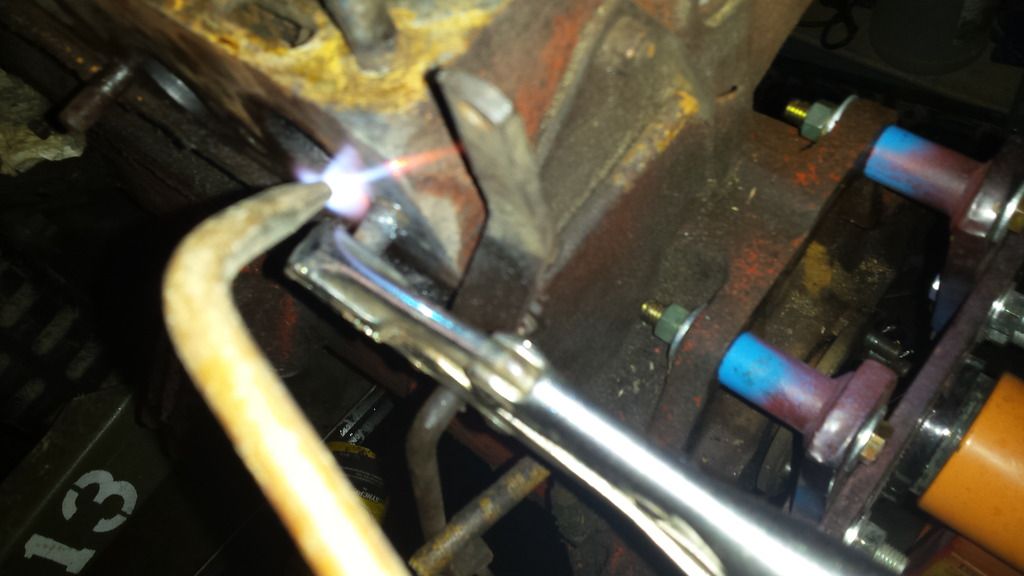

What I did was heat up around the bolt and spray with PB Blaster. Then heat again and spray again.  I then used the vise grips I had attached as the bolt removal sockets I tried were crap. With it heated and PB Blaster applies it came out just like cutting butter. Sweet and easy. Surprised the crap out of me. That's for sure. I did the same with the water pump bolts and they came out just as easy.  |

|

|

|

Post by zooke581 on May 3, 2016 20:27:56 GMT -5

Now on the forward broken bolt of the exhaust, this one broke off slightly recessed.  What I needed to do here was first use a drift to flatten out the surface to be able to find center with a punch to guide the drill bit. Once a had a hole big enough to try an easy out I did the same thing as the other bolts. I heated applied PB Blaster heated and applied again. Then I tried the easy out. I did not budge. For fear of breaking the easy out I continued to drill the hole bigger going thru each next size bit till the hole was the size of the other good threaded holes. I then took my tap and tapped out the existing threads that were already there. I believe it was quite the stroke of luck to get it exact without a jig.  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on May 4, 2016 5:17:01 GMT -5

Like walking on egg shells. Well done! You are a winner. The heat you used was what really did the trick. Should be a easy finish for you now. Oilly

|

|

|

|

Post by zooke581 on May 4, 2016 20:16:03 GMT -5

Thanks Oilly. Did a lot more today. Mostly cleaned off all mating surfaces and cleaned buildup on coolant passages. Cleaned and rethreaded all the head bolts and nuts. Had to heat three of the nuts to get them off the studs that came out of the head. These will be sealed when they go back in the head. Very tedious work. Also prepping for the arrival of the valve spring compressor from Jeff. Took a gander at the exhaust manifold and noted that the heat riser was free. That's a good thing. But...the mating surface was badly pitted and as I turned it over, a large crack in the exhaust manifold. That sucks...  So what does one do when a catastrophe of this magnitude of this happens? You go to your 3 year old stash of parts and grab another manifold. Forgot it was there till I saw the crack. This one is much better, no pitting on mating surfaces, no cracks but...I do have to free the heat riser.  |

|

|

|

Post by Haines Garage on May 5, 2016 6:35:05 GMT -5

Those manifolds.

Crack crack crack- a - lack. I have retired many I have bought or had to the junk yard. The one I have on the engine came from Sir Leemeister. That is an extremely common deal. Unfortunately the repops are not correctly machined for the most part.

Or so I am told.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on May 5, 2016 7:10:39 GMT -5

The omix ada manifolds will shed the bushings for the heat riser shaft. Original is the way to go. Check your mating surface for flatness too! That one looks good! Soak and tap the shaft front to back. Inside and out. I've had good luck freeing them up. Oilly

|

|

|

|

Post by zooke581 on May 6, 2016 21:12:50 GMT -5

Well today when I got home there was a nice little surprise waiting for me. The valve spring tool Jeff sent me to use. Thanks friend for the loan and quick shipment. Well after feeding the dogs and eating dinner it was off to the garage. Guess what I did tonight?  This is quite the nice little tool. Make short work of removing and installing the valves. The cleaning and lapping was a whole nother story. Tedious work that.  Here you can see the difference. Ones on the right done and shiny valve stems. Dirty ones on the left. After the valve work I did a little more cleaning on the block and chased down a few more bolt threads. Next to free up the heat riser.  |

|

|

|

Post by Ryan_M on May 7, 2016 5:54:01 GMT -5

Harbor Freight has the 1 ton cherry picker for $178. Guess I'll get that. Going to need it a few times. I bought one of these for about $120 with a coupon. It's a life saver. My only gripe is the arm does not extend far enough to easily reinstall the motor. The vertical part of the hoist hits on the front bumper before you can push the engine all the way "home". Makes things a little tricky. I don't have a load leveler but am wondering if I did it might buy me the couple extra inches needed. Here was the method prior to my engine hoist. Not good.  |

|

|

|

Post by Ryan_M on May 7, 2016 5:56:15 GMT -5

Unfortunately the repops are not correctly machined for the most part. Or so I am told. Confirmed. They are garbage. You will need to drill a perfectly good exhaust manifold to compensate for an incorrectly drilled intake manifold. |

|