|

|

Post by Haines Garage on Jul 6, 2013 18:18:22 GMT -5

This is fun to watch. Have I told you how cool I think your garage is? Tim Thanks Tim! Its actually where I am most of the time. You need to see it in person  |

|

|

|

Post by Haines Garage on Jul 6, 2013 18:28:38 GMT -5

|

|

|

|

Post by Haines Garage on Jul 8, 2013 17:52:51 GMT -5

These are the casting #s and blasted casings, before rebuild. The top photo is of the inner rebuild. New bearings, syncros, All internal parts are taken apart cleaned, and re-assembled. Case is primed and painted. |

|

|

|

Post by Haines Garage on Jul 8, 2013 18:20:51 GMT -5

Its about to get HEAVY! But I have to mow the grass before the sun goes down on Chucktown  . Lot of rain lately here you know.... |

|

|

|

Post by Haines Garage on Jul 9, 2013 18:58:27 GMT -5

THIS IS IMPORTANT I FEEL AND STORY NEEDS TO BE TOLD. After I rebuilt the Trans-mussion, and Transfer Case, I was having an extremely hard time mating the two back together, The bolts that attach the two units are various and IMPORTANT lengths, eXPessially ;D the small bottom bolt that is near the reverse idler gear!! In trying to mate the two, I was binding my units up on the final torque on the bolts. There are two reasons for this #1) T style replacement keepers for the Cluster Gear shaft, and reverse idler gear shaft are INCORRECT and wont fit into the machined area on the transfer case. #2) Repro gasket kits ARE NOT THE CORRECT THICKNESS! And are missing one , in my OPINION , one very important Gasket. In my frustration, my wife says you have these friends, why don't you call them and ask... I am stubborn , I know what I am doing, don't need to....After a few days of many failed attempts , I do. I am told to make a gasket out of a cardboard box, grind the bottom bolt, Use RTV...all wrong However the make my own gasket thing appeals to me ( For the T90 to D18) surfaces. I buy mineral fiber material by Mr. Gasket, and cut my own using an exacto knife, and a pattern from the 6!! Gasket kits I bought.     When I realize the t keeper is wrong, and the gasket has been made, low, and behold the two sufaces mate, and my units spin freely!   Think on this my friends...the next part of the story will come tomorrow. If there should be any partys wishing to ague at this point, please start a new thread...we are not doing it here in MY BUILD  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jul 10, 2013 9:57:55 GMT -5

THIS IS IMPORTANT I FEEL AND STORY NEEDS TO BE TOLD. After I rebuilt the Trans-mussion, and Transfer Case, I was having an extremely hard time mating the two back together, The bolts that attach the two units are various and IMPORTANT lengths, eXPessially ;D the small bottom bolt that is near the reverse idler gear!! In trying to mate the two, I was binding my units up on the final torque on the bolts. There are two reasons for this #1) T style replacement keepers for the Cluster Gear shaft, and reverse idler gear shaft are INCORRECT and wont fit into the machined area on the transfer case. #2) Repro gasket kits ARE NOT THE CORRECT THICKNESS! And are missing one , in my OPINION , one very important Gasket. I n my frustration, my wife says you have these friends, why don't you call them and ask...

I am stubborn , I know what I am doing, don't need to....After a few days of many failed attempts , I do. I am told to make a gasket out of a cardboard box, grind the bottom bolt, Use RTV...all wrong However the make my own gasket thing appeals to me ( For the T90 to D18) surfaces. I buy mineral fiber material by Mr. Gasket, and cut my own using an exacto knife, and a pattern from the 6!! Gasket kits I bought.     When I realize the t keeper is wrong, and the gasket has been made, low, and behold the two sufaces mate, and my units spin freely!   Think on this my friends...the next part of the story will come tomorrow. If there should be any partys wishing to ague at this point, please start a new thread...we are not doing it here in MY BUILD  And when she asks you to use a map when lost you don't do that either...of course you wouldn't...we are men and that's how we do. ;D |

|

|

|

Post by Haines Garage on Jul 10, 2013 21:23:14 GMT -5

That is very Funny , and how true! ;D ;D ;D ;D ;D

|

|

|

|

Post by Haines Garage on Jul 10, 2013 21:36:53 GMT -5

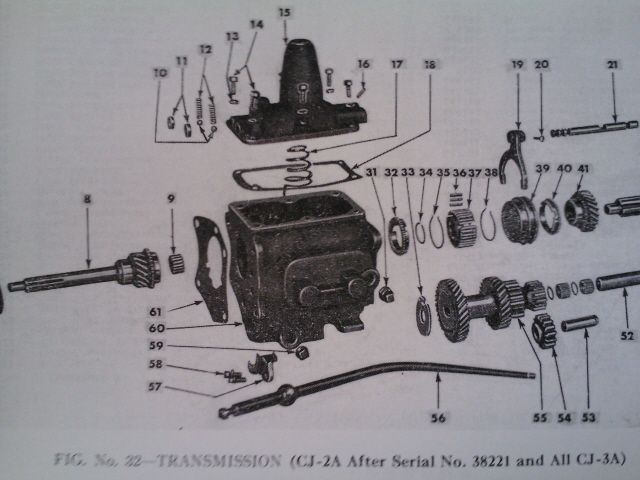

Second part of the story. I am told, no matter what you do the Transfer Case, and Transmission will leak.. I don't want to believe that.... Internet research shows interesting things... Mainly this  Notice part 61 in the drawing  |

|

|

|

Post by Haines Garage on Jul 13, 2013 21:55:56 GMT -5

There are two spots where I find the elusive Bell housing to transmission gasket exist. The first came from Rick, the Scout Pilot. He had an unmolested drive train that when he diss-assembled, was able to retrieve a slightly torn, but good for a pattern gasket. This was a FANTASTIC FIND (Thanks Scout!!) The second spot was on the 2a pages posted by another member. In discussing this with, Rick (Scout Pilot), Myself, Paul(The Hillbillis) , and Ricks son, at a get together in NC, we brain storm about this gasket problem. We talk about cutting gaskets, This would be great to put back out there in the Flat Fender World. Perhaps solve some of the leak spots on the drivetrain. (There are more  ) The Scout Pilot cut 2 prototypes from his original and sent them to me. So I had a pattern for the bell housing to transmission, and a mating gasket to the transfer case. I was in a local auto parts store, and was looking to purchase some material to cut some prototypes of my own. Talking with some mechanics in line, I find a local company that specializes in gasket making!!! I drove past that building so many times and never even paid attention to it. I immediately drive to the location with the prototypes. Long story short, 200 sets of 1/32 mineral fiber, and 200 sets of 1/32 rubber gaskets are produced. Some were sold to a vendor, and the person whom "split the bill" with me on the manufacture cost, and I split the remainder of the order. These are the gaskets listed here in the for sale items. I use them for the assembly of my drive train. Thats a story for my next post. Again, should there be any argument about this topic, please in another thread. I am just explaining "My Build Here" |

|

|

|

Post by Haines Garage on Jul 14, 2013 21:36:26 GMT -5

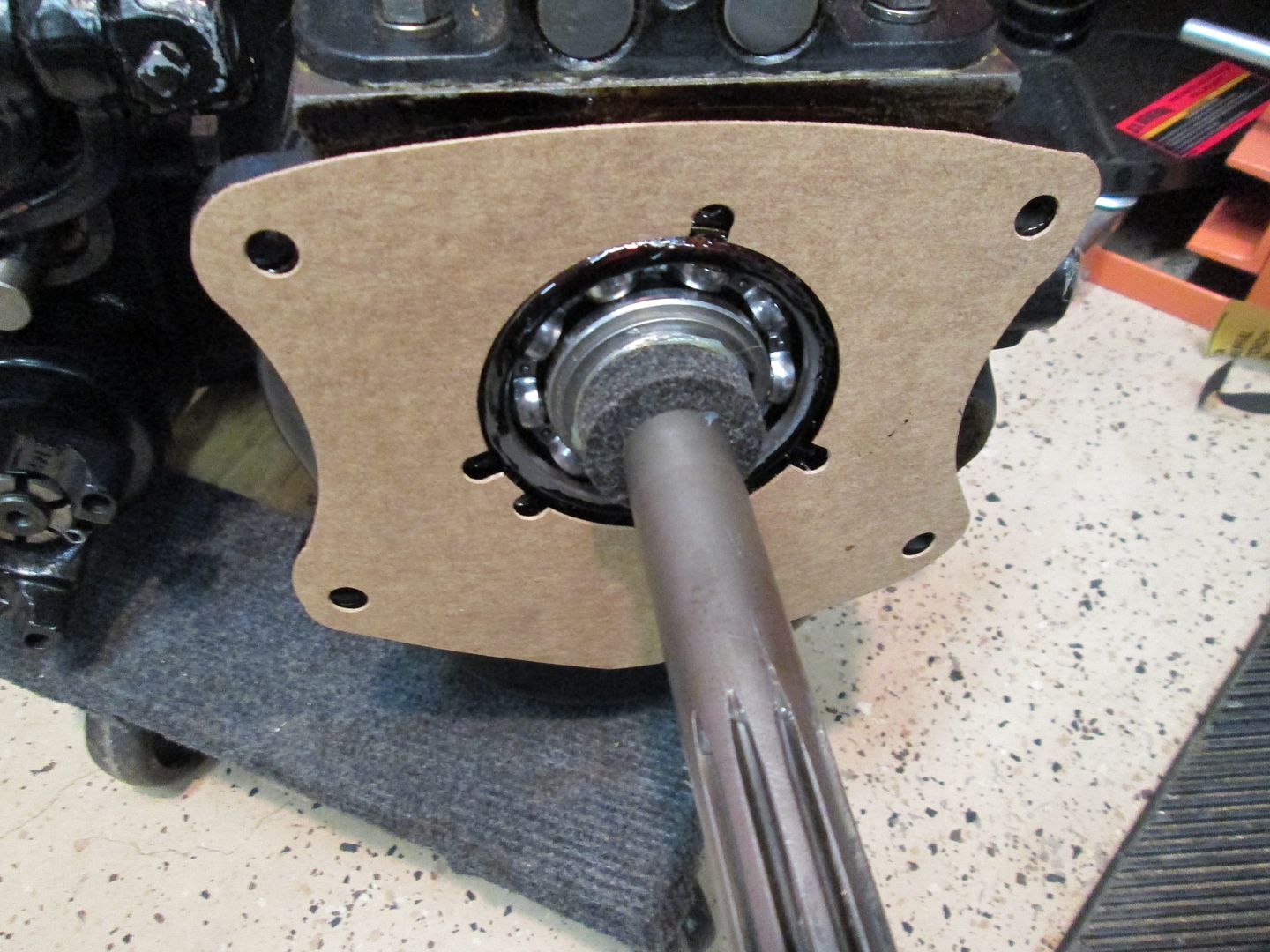

Here we go ....  leak points on the front of the T90 Trans-Mussion Shown with the K-nif ;D ;D ;D  [imghttp://i1362.photobucket.com/albums/r683/HainesGarage1946CJ2A/IMG_0161_zps817235d5.jpg][/img]  RTV WILL NOT FILL THE TIGHT TOLERENCES FOR LONG  Assembly is like this  Gasket is sealed to transmission face( DEAD CLEAN) with Permetex Indian head shellac.  Front cap is attached , again using the Indian Head Shellac as as sealant, bolts are torqued to spec as per Willys manual. http://i1362.photobucket.com/albums/r683/HainesGarage1946CJ2A/IMG_0164_zpscbfa751a.jpgBell hosing again has been cleaned and cleaned, Indian Head Shellac between mating surfaces. Original bolts torqued to manual specs.  |

|

|

|

Post by athawk11 on Jul 15, 2013 9:59:05 GMT -5

Looking very nice.

HG was kind enough to send me a set of these gaskets. I am not at a point where I can use them yet, but I am very hopeful they will be the answer to a leaking front side tranny!

Tim

|

|

|

|

Post by Haines Garage on Jul 15, 2013 22:29:38 GMT -5

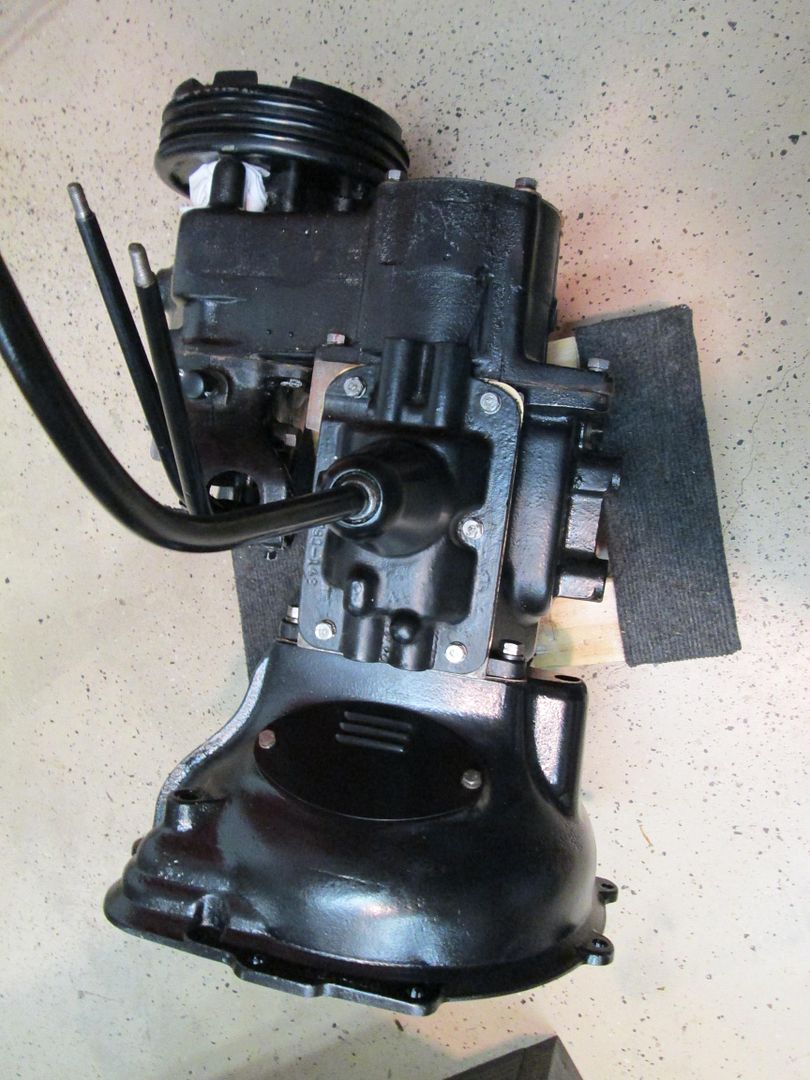

Finished assembly  |

|

|

|

Post by Haines Garage on Jul 15, 2013 22:39:49 GMT -5

|

|

|

|

Post by Haines Garage on Jul 16, 2013 21:31:12 GMT -5

|

|

|

|

Post by Haines Garage on Jul 17, 2013 21:21:38 GMT -5

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jul 17, 2013 22:25:26 GMT -5

Very nice!, love the personal detail  Lee  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jul 17, 2013 22:28:00 GMT -5

looking good scott.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jul 19, 2013 6:54:25 GMT -5

Yup, McLovin that yard art, Haines. I'm going to give the HOA a call on their crime hotline.

|

|

|

|

Post by Haines Garage on Jul 19, 2013 18:04:15 GMT -5

Yup, McLovin that yard art, Haines. I'm going to give the HOA a call on their crime hotline. Not even Funny!! I almost have been busted half a dozen times with the sandblaster in the front yard, or a part hangin' in the 'ole Paint Tree  |

|

|

|

Post by Haines Garage on Jul 19, 2013 18:11:10 GMT -5

Very nice!, love the personal detail  Lee  Sir Leemeister, I have stamped hidden and inscribed all kinds of little "details" on Grandpas Jeep. Some #s I only know the meanings of. that I will never tell a soul.  When Scott the second inherits this, he is going to be in for a few surprises...... ;D ;D ;D ;D ;D  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jul 20, 2013 22:50:50 GMT -5

but will he understand the numbers?? best to write these things down in a lil book and pass it along.

|

|

|

|

Post by Haines Garage on Jul 21, 2013 19:41:24 GMT -5

but will he understand the numbers?? best to write these things down in a lil book and pass it along. no worries 'Ole Friend...I did  |

|

|

|

Post by athawk11 on Jul 22, 2013 10:51:06 GMT -5

This is not as cool as your personal touches, but I am trying to keep track of the parts that were provided, by the Willys community, toward the rebuilding of Whitey. That way I can have a piece memorabilia that can be passed on to the next owner after I'm long gone. He/she will have an interesting piece of history to thumb through.

Your personal touches inspire me.

Tim

|

|

|

|

Post by Haines Garage on Jul 23, 2013 21:26:57 GMT -5

This is not as cool as your personal touches, but I am trying to keep track of the parts that were provided, by the Willys community, toward the rebuilding of Whitey. That way I can have a piece memorabilia that can be passed on to the next owner after I'm long gone. He/she will have an interesting piece of history to thumb through. Your personal touches inspire me. Tim That is a Great way to look at a restoration. It's just a fact, someday someone else will own these Jeeps. Weld a tube under the front dash  . A scroll of the build. Future owner will talk for hours, and wear his friends ears off...I love It!. Don't have much left to contribute, but I gots to get in on this! ;D ;D  |

|

|

|

Post by Haines Garage on Jul 23, 2013 21:33:00 GMT -5

Here is a little sample of what I have done  .   And for you perfectionist out there...I could have made the letters perfectly straight, however that's not the Willys way  |

|