|

|

Post by Haines Garage on Apr 16, 2015 18:25:06 GMT -5

And while we are on the subject Ryan the Axehandle that you purchase that won't fit correctly into your m38.

It is too thick in the curvature of the handle is incorrect.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 16, 2015 19:28:40 GMT -5

The shield slips off and goes into the pouch for it. I don't have the pouch. Altogether, it folds into the handle. I was told when I bought it that it was late WWII, PTO/CBI issue.

|

|

|

|

Post by Ryan_M on Apr 16, 2015 20:04:28 GMT -5

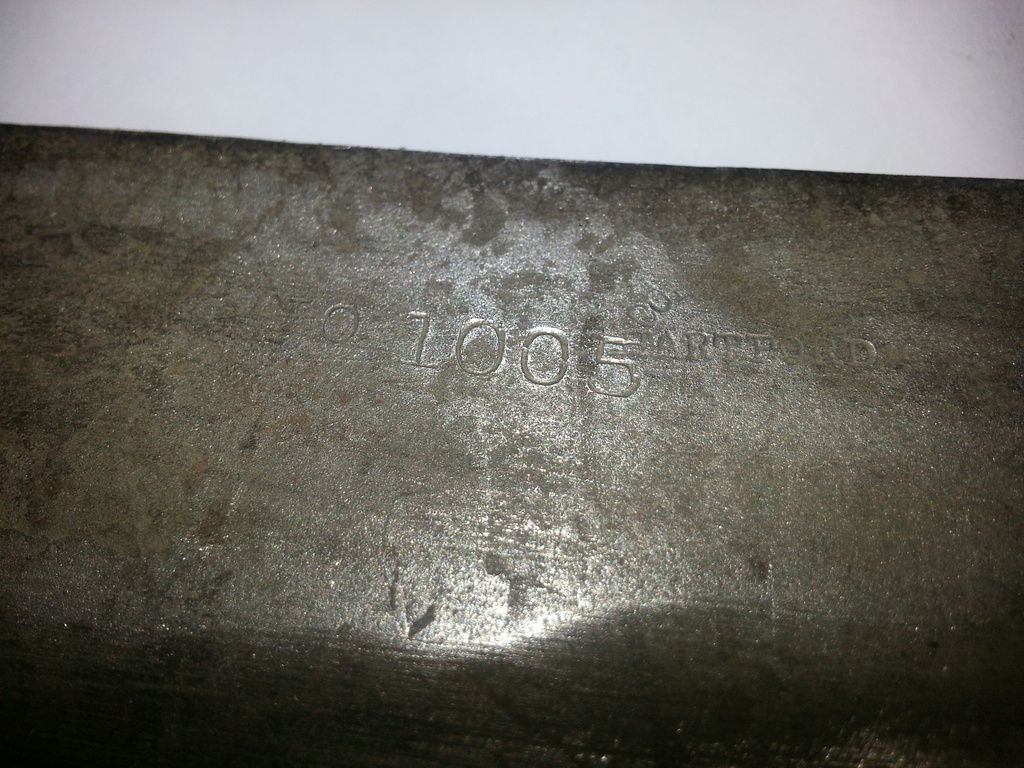

HG - The "Collins & CO" is all but worn off but "Hartford" and "No 1005" are still legible.  |

|

|

|

Post by Haines Garage on Apr 16, 2015 20:40:55 GMT -5

I love it ! You have some of the coolest things in the planet!

I am Jello ness!

|

|

|

|

Post by Haines Garage on Apr 16, 2015 20:44:45 GMT -5

|

|

|

|

Post by zooke581 on Apr 16, 2015 21:43:44 GMT -5

HG, there was no sheath. I go back and see what the price is.

|

|

|

|

Post by jeffwho on Apr 17, 2015 7:25:59 GMT -5

HG I think I will just stamp a few twirly "F"s into my axe head next to where it has "China" stamped, that'd make it authentic right?

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 17, 2015 8:06:30 GMT -5

You should branch out and start making "Sierra Clubs". Only for sale to non members of that particular club. Oil

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 9, 2015 7:41:50 GMT -5

Here are a few pics of an axe i'm restoring as a Christmas gift for my 10 year old son. Its a 1936 Sears Craftsman Golden Jubilee hatchet. The handle is Shag Bark Hickory that he and I split out into handle blanks earlier this year. I still have to transition the handle into the head, and I have to wedge the handle in and sharpen the blade. But first, I want to put a protective finish on the hatchet. My son is 10 and I want to protect the metal from minor abuse. It will mainly be used for carving out spoon blanks. I like the idea of using gun blue, but there are minor pits and discoloration in the blade so I don't think it will coat the way I want it to.

Any suggestions?

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 9, 2015 8:26:59 GMT -5

Parkerise it?

|

|

|

|

Post by jeffwho on Dec 9, 2015 8:32:07 GMT -5

When I asked a guy I know who knows his guns, he suggested I use CeraKote on the BAR I am going to use as a display piece. It's claimed to be more durable and comes in a variety of hues same as parkerising. Just a thought - if I ever get that done, I will put up some pics here or PM.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 9, 2015 9:36:34 GMT -5

Jeff,

It seems like cerakote is an applied material, like paint. I think swinging an axe into wood will wear or chip the finish. I have jappaned tools and other things in the past, and that requires an oven treatment too. But I wouldnt jappan an axe.

However, it seems like parkerizing reacts with the metal to change the color. Therefore, there is no buildup on the blade.

I am considering it though. I want it ready for christmas so I have to get cracking.

Thanks for the input.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 9, 2015 11:58:22 GMT -5

Cerakote™ is a very durable finish for a Browning Automatic Rifle, but not for an axe. There are two formulas. One is heat-cured and the other is an air-cure. I use the air cure on the carbs, pumps and filters. My son, Muskrat is continually busy doing firearms with the heat-cure formula.

|

|

|

|

Post by Haines Garage on Dec 9, 2015 19:46:03 GMT -5

Cold Blue would be a treatment that would work for your application. I have done axe heads this way. It will not chip off or crack. The pits in your head can be ground out. However, it is a vintage piece. Imperfections are to be expected. If you chose to grind, use a light touch. In that I mean do not be aggressive with the grinder, Use 80. 120. then 240 grit sandpaper. your handle is mounted, so tape before you Blue as not to stain it. Very cool project.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 10, 2015 6:33:27 GMT -5

Haines,

Thanks for the suggestion. I don't think I want to sand out all the pits on this head. I don't have the time, and this is an axe head for a 10 year old. The handle is only fitted, not mounted.

I am leaning towards Parkerizing. From what I've read, the discoloration wont effect the finish and I wont be able to see the color difference in the finished product. And if it comes out nice, I can treat my other hatchets and axes that I use a lot. They will have to have the handles removed for treatment, but I've been wanting to re-haft them for a while.

However, Parkerizing is more involved. Heating the solution, etc. But I like experimenting and from what I've read about blueing and what you've suggested, the steel has to be flawless to get a nice finish. I don't want to take off that much steel on my old Collins or norlund.

I will post pics of the finished product. I have to order the chemicals. I hope I get it done before Christmas...

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 10, 2015 7:13:38 GMT -5

I parked one of my firearms and you will find it will not stick to any impurities. Blasting the metal perfectly clean and dry with no hand prints or oils is a must. Looks awesome when it turns out right. John

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 10, 2015 12:48:47 GMT -5

Needed for proper prep:

Clean, clean, clean.

Nitrile gloves

a few minutes in Acetone as final step before finishing.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 11, 2015 7:35:27 GMT -5

Thanks everyone,

I ordered a Parkerizing kit. I have a media blast cabinet that I will use to blast the hatchet before I parkerize it, and I will keep it clean, clean, clean!

Thanks for everyone's advice. I will post pics of the finished piece

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 18, 2015 21:46:48 GMT -5

Hello everyone. I thought I would post the results of my Parkerizing experiment. I received the kit today, so I un-hafted two other hatchets that I use all the time.

Here they are before sandblasting. Obviously they are pretty raw, and the broad axe is used on green oak, so the rust is an issue.

I decided to try and parkerize my K-bar that I use all the time. However, I guess its stainless sleet because it didn't react with the chemical. Here they are after sandblasting and before cleaning.

Lots of bubbles in the hot chemical bath. They were in there for about 30 minutes. I kept them in until the bubbles from the reaction slowed to a crawl. When they first went in, there was a lot of reaction and a lot of vapor.

After the chemical treatment, washed off, and waiting for oil.

Oiled and shiny. This is interesting and surprising. The etching reacted differently with the different parts of the steel. First, my broad axe is very old. The brown stripe is because of impurities in the steel. You can see the linear grain structure, reminds me of a tree. And there is a strip of good steel at the edge.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 18, 2015 22:07:42 GMT -5

Above is a closer pic of the broad axe.

Below is the hatchet that started all of this. Incase you cant see it, its a Craftsman Golden Jubilee from 1936. I am restoring this as a Christmas gift for my son. Here you can really see the good steel/normal steel delineation. They used a lot of good steel to make this axe. The good old day of tool making...

And last but not least, My Norlund that I use all the time. Again, you can easily see the different steels.

This was a fun learning experience. They didn't come out with a NASA finish, but considering the age of each one, and the amount of rust that I've had to deal with, I am happy with the outcome. Now I have to sharpen everything, make a few more handles and put them to use. I'm curious to see how they hold up. However, even if I wear down the finish near the cutting edge, most of the head will be protected from rust. I hope. |

|

|

|

Post by surveypunk on Dec 18, 2015 22:13:21 GMT -5

Curious. Is the cutting edge of the tool you call a "broad axe" head flat on the other side? If so, it would be called a "hewing axe", and needs a nifty offset handle. Hard to find now.

Neat-o!

JB

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 18, 2015 22:32:10 GMT -5

And on a side note. Im looking for another broad axe (single bevel) like the one I parkerized. I have found that style, weight, cutting geometry, perfect for me. I have bough several others and they suck. Or, I should say that I don't perform well with them. The others are mostly too lite dont sink into green oak. I am ambidextrous and I like switching hands when fatigue sets in, and swinging at oak makes that happens often.

So, the specifics of the broad axe is... 2 lbs, 9oz. cutting edge is about 5.25 long, and it is about 8.5 inches from edge to poll. Its marked U.S.A, Collins, and Legitimus. It has other writing within, but I cant really make it out and I don't think its relevant to finding its sister. But if anyone is interested, here is a better pic.

If anyone comes across one, please let me know.

Thanks for the suggestion to parkerize.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 18, 2015 22:40:13 GMT -5

Hey Punk,

Yes, it is a hewing axe. They go by a few names. I hew oak to make furniture. It is flat on one side and beveled on the other. This one has near perfect geometry. It is slightly curved (convex) from top to bottom along the back. It is easy to control the cut. I reshaped the cutting edge for control also. And the weight is great for a solid hit into oak. The lighter axes want to bounce back. Of all the hewing axes I've used, I like this one the best by far. And now I get to make a new handle since I drilled the old handle out in order to parkerize it. lol. I guess I wont be making much furniture until I get that done.

I don't use or need a crook handle. My hands are away from the board (most of the time).

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 18, 2015 23:03:54 GMT -5

Hey Punk, Yes, it is a hewing axe. They go by a few names. I hew oak to make furniture. It is flat on one side and beveled on the other. This one has near perfect geometry. It is slightly curved (convex) from top to bottom along the back. It is easy to control the cut. I reshaped the cutting edge for control also. And the weight is great for a solid hit into oak. The lighter axes want to bounce back. Of all the hewing axes I've used, I like this one the best by far. And now I get to make a new handle since I drilled the old handle out in order to parkerize it. lol. I guess I wont be making much furniture until I get that done. I don't use or need a crook handle. My hands are away from the board (most of the time). Can you post some pics of you oak furniture?  Its good to see a telented man's work!! |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 18, 2015 23:32:42 GMT -5

Yes. I will take some pics tomorrow

|

|