Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 12, 2014 10:04:25 GMT -5

Bo, thanks for letting me stay, look under my avitar  Lee  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 12, 2014 10:20:54 GMT -5

|

|

|

|

Post by athawk11 on Jan 12, 2014 20:17:13 GMT -5

HG,

I know it's frustrating, but we all learn by making mistakes.

I really enjoyed the HG Do Jo!!!! Cracks me up .

Tim

|

|

|

|

Post by Haines Garage on Jan 12, 2014 22:02:08 GMT -5

Glad you like it Sir Hawkridge...more to come...............!!!

|

|

|

|

Post by rudycon on Jan 13, 2014 10:30:47 GMT -5

Side gear clearance spec?

Is there a specification for the side gear clearance between the gears and the housing? Can I stack shims to tighten up the sidegear lash?

I have taken out the welded spider gears in my rear Model 41 and replaced it with "stock" parts from walcks. (by the way, the Walck's cross pin is too long on the non-drilled side by about 1/8" I ground it off so I could get the ring gear back on. First time I've ever had to do that in a differential.

I find that there is quite a bit of room between the side gears and the spider gears (probably wear on the differential carrier?) Any reason I can't double up on side gear shims to get the gears to mesh a little tighter?

Thanks!

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 16, 2014 0:49:54 GMT -5

I can't say it's "right", but I have done that. BW

|

|

|

|

Post by Haines Garage on Jan 19, 2014 21:55:06 GMT -5

I wanted to correct the mistake I made...   ...without destroying my Timkens. I bought a piece of 12 inch long, Galvanized pipe, 1 1/2 diameter. It fit perfectly around the shoulder of the axle shaft. It rested on the inner sleeve of the bearing, with out touching the roller cage. I added a cap, in order to have something to smack with my BFH! It worked like a charm!!   !  I had the wrongly istalled bearings off, cleaned, repacked with grease, and installed correctly within an hour.... Next we check the endplay  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 19, 2014 22:20:51 GMT -5

Hey make sure you put that new service tool on the never ever to be used for that purpose again shelf  Lee  |

|

|

|

Post by Haines Garage on Jan 19, 2014 22:23:05 GMT -5

True That Sir Leemeister...True That..Thanks again for the eyes! and advice.

|

|

|

|

Post by Haines Garage on Jan 21, 2014 23:11:48 GMT -5

With axles back in correctly, I soaked the original shims in "The Works" They came out like new. I had them tagged and bagged, drivers side, and passenger side. Believe me or not, I installed them back into their original locations, and got a perfect .003 endplay reading!! Go figure...   |

|

|

|

Post by Haines Garage on Jan 21, 2014 23:22:39 GMT -5

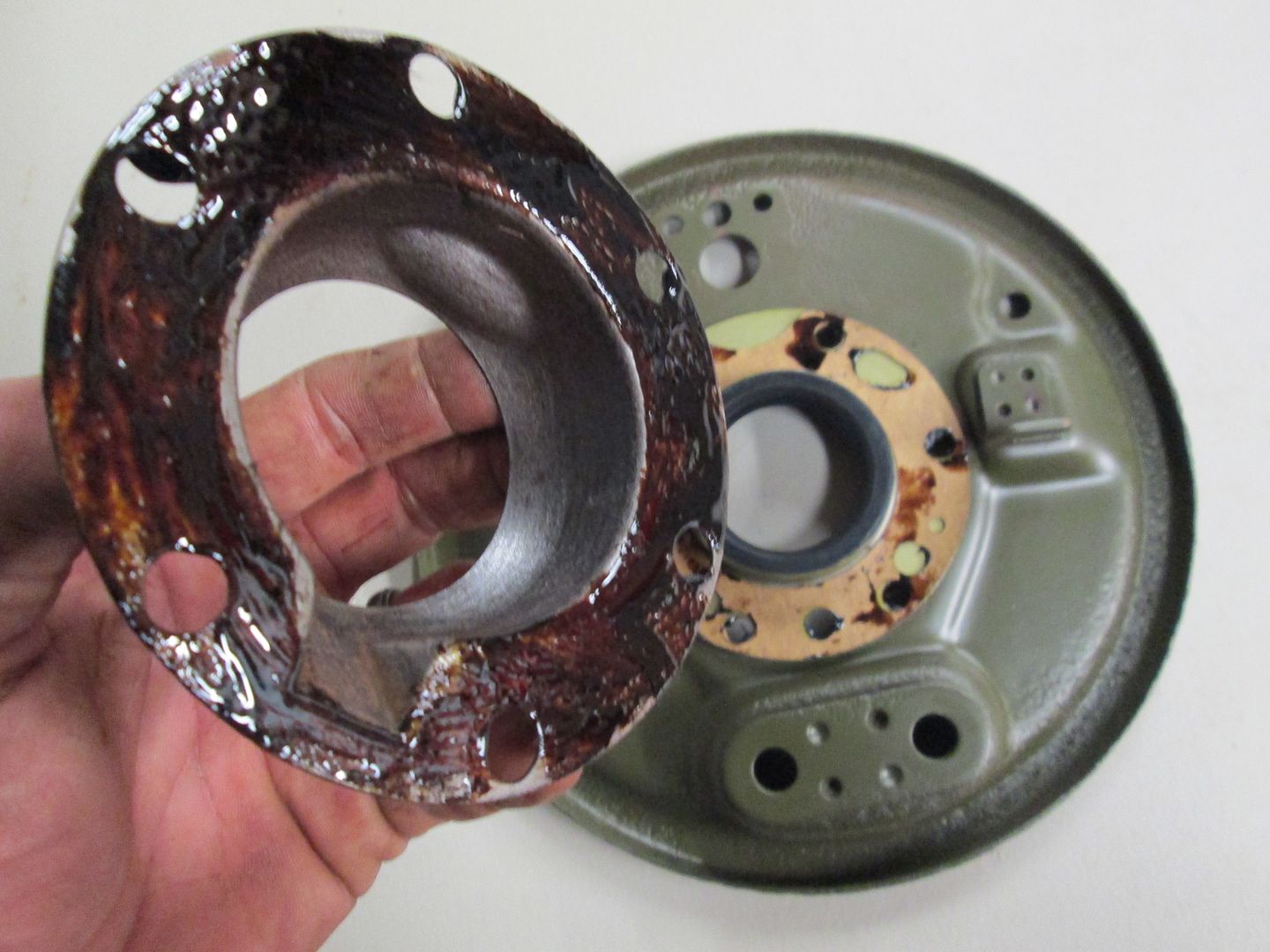

Now the fun Starts.... Here is how I installed The brake backer plate, gaskets, grease retainer, and grease protector... Parts laid out on the table  I install 1st gasket , using Indian Head Shellac, onto the brake backer plate I apply shellac to the grease retainer  I apply shellac to the second gasket, and install.  I apply shellac to the grease protector, and install  I install all the bolts, lining up the gaskets  I then install my spacer, then shim pack.  I simply line up the bolts into my axle housing after that. Install the lock washers, and torque to 35 ft pounds.  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 21, 2014 23:41:16 GMT -5

scott 2 things first for your shims when you soaked them in the works what did you do after you pulled them out to neutralize it and prevent rust? 2nd on my truck the bolts for the brake retainer go in from the axle side and the nuts are on the brake plate side by the grease seal you just did above. now i am not sure if that is the way on my jeep if you have a photo of taking it apart just double check so you don't have to pull the drum off to fix it if it is the other way.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 22, 2014 19:20:07 GMT -5

scott 2 things first for your shims when you soaked them in the works what did you do after you pulled them out to neutralize it and prevent rust? 2nd on my truck the bolts for the brake retainer go in from the axle side and the nuts are on the brake plate side by the grease seal you just did above. now i am not sure if that is the way on my jeep if you have a photo of taking it apart just double check so you don't have to pull the drum off to fix it if it is the other way. I AM IMPRESSED THERE LUKE...GOOD EYE FOR DETAIL , GUESS HAINES GARAGE IS GETTING TOO ANXIOUS TO GO AROUND THE BLOCK ON HIS ROLLING CHASSIS..  |

|

|

|

Post by Haines Garage on Jan 22, 2014 22:32:18 GMT -5

Yes Sir, Sir Schimmster pointed out a flaw! GLAD YOU DID! If you Google Dana 41, you will see two different variations of the bolt patterns. I changed them out tonight to the Correct placement...I found it in an old axle photo, as well as in Sir Hawkridges Whitey Build. However...Google it for yourself to see what I am talking about  So the moral of the story is ..Don't trust what you see on the internet...Trust the Members at Haines Garage!!! Thank You Sir Schimmster..!!! I appreciate you and your input  Here we are.. I stand corrected Luke, ..your an OAK!  |

|

|

|

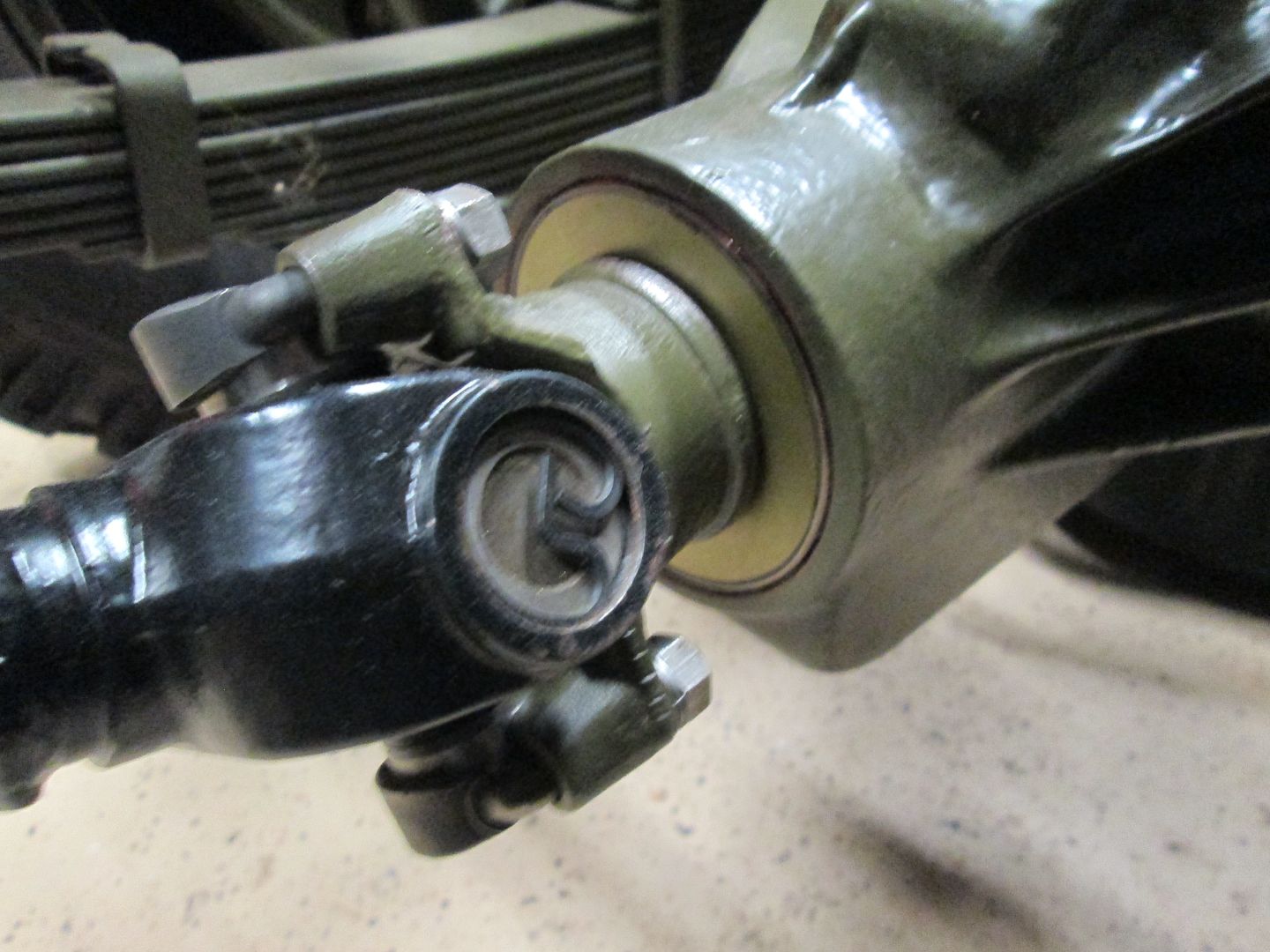

Post by Haines Garage on Apr 3, 2014 17:57:26 GMT -5

To finish up on the rear Dana 41 axle thread, I installed a speedy sleeve on the original yoke, and installed a new seal. The axle now rests attached to the rear drive shaft with new universal joints installed.  |

|

|

|

Post by Garry on Feb 14, 2016 21:39:25 GMT -5

how do the axles come out of the dana 41? are they pinned/c clip or can I use a slide hammer to pull them.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Feb 14, 2016 22:11:03 GMT -5

Howdy!

Once you remove the grease catcher thingy, backing plate, retainer ring, etc.... The axle shaft and tapered bearing/race should pull out. I usually had to use a little persuasion from a slide hammer.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 5, 2016 9:46:01 GMT -5

Mr. Haines and group I have a question on your installation of the carrier bearing caps. First f I know you marked your caps before you removed them and reinstalled them that way. However when I did mine I marked mine like you did and reinstalled them that way. A friend of mine said I had installed them wrong and that the caps were switched at one time. He said the caps and banjo housing are marked a special way so they go back on they same way because they are line bored when made. If you look at yours there is 4 stamped on the housing and cap. The 4's should match on each side one is vertical the other side horizontal . My friend says it makes setting up your axles easier. Has anybody heard about this and does it make a difference ?

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 5, 2016 11:55:08 GMT -5

Welcome Tom, nice to have you here at the HG!........... I will look into this, per manual, BUT, as your friend said the housing is line boared, therefore I do not believe you could reverse the caps and properly retorque them without a serious bind..... Precision is at a hi degree in this area and you cannot swap things around without fitment problems. Perhaps others will chime in.

Lee

|

|

|

|

Post by Haines Garage on Mar 5, 2016 18:58:59 GMT -5

It's been a while since I did the rear axle. I took pictures for my own reference before I took anything apart. I also tagged and bagged the local . Placed in plastic marked bags. I have never claimed to be an expert. These threads are how I rebuilt my Jeep. I hoped that sharing would be helpful to others.

If anyone has something to add to these threads .

Please do so.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 6, 2016 9:28:55 GMT -5

Scott, I hope I did not offend you by asking about the carrier caps. I by no means am an expert. I really , really appreciate this forum and the time and effort you take to post your build here and Facebook and run this forum . It's folks like you that make this Willis hobby enjoyable. As rookie in this hobby I hope I can add something back to it in the future.

Birddog

|

|

|

|

Post by Haines Garage on Mar 6, 2016 9:59:41 GMT -5

Not at all my friend.  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 6, 2016 11:03:30 GMT -5

Scott, I hope I did not offend you by asking about the carrier caps. I by no means am an expert. I really , really appreciate this forum and the time and effort you take to post your build here and Facebook and run this forum . It's folks like you that make this Willis hobby enjoyable. As rookie in this hobby I hope I can add something back to it in the future. Birddog , we all have levels of expierience, most have little in the differentials myself included........ Mr Birddog, you are no rookie!  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 6, 2016 14:14:32 GMT -5

Welcome aboard "rookie"! I mean birddog7!! LOL  |

|

|

|

Post by ISAAC on Sept 3, 2016 3:14:00 GMT -5

hi , great jpb on the entire build, where did you find the parts

|

|