|

|

Post by Ryan_M on Mar 28, 2016 10:42:34 GMT -5

I installed the MB motor in the red 3A over the weekend. I have much to say about the entire process but this post will focus only on the starter issues.

For the swap I installed an MB motor with original flywheel and a NEW 124 tooth ring gear on it. I used the same 3A bellhousing.

When I depress the foot pedal to start the jeep the starter grinds on the ring gear. The Jeep will start but something is not right. I checked the old 3A motor to confirm that flywheel also has a 124 tooth ring gear - it does. Not sure if maybe the starter is spinning before it meshes with the ring gear? Is there an adjustment on the starter for this? What could be different here to cause the grinding? MB and 3A flywheel should be the same, right? The new ring gear fit so I took that as a good sign. Is there something else I should be looking for?

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 28, 2016 15:12:53 GMT -5

I'm confused (don't be shocked).

An original MB flywheel should have 97 teeth, I believe. Is the flywheel on the MB engine your old flywheel or the flywheel that came with the MB engine?

How about the starter...I'm assuming it's your old starter, right?

And you mentioned the flywheel has a new ring gear. Did you install it? Where did it come from? Did you count the teeth?

I've almost got to believe that the bendix matches the fly...I don't think they'd mesh at all otherwise. How about a bent armature shaft or when installing the starter, you somehow didn't get it lined up perfectly?

|

|

|

|

Post by Ryan_M on Mar 28, 2016 15:25:46 GMT -5

Moose - You are correct. An MB ring gear has 97 teeth. That's why I smashed it off the MB flywheel and replaced it myself with a supposed NOS 3A ring gear from QTM parts. The new ring gear has 124 teeth. Same number of teeth the old motor/flywheel had that this starter ran fine with.

I need to pull the starter and take another look. Maybe something will jump out at me.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 28, 2016 15:45:21 GMT -5

You put the ring gear on with the slight bevel on the teeth forward? If that is good, then there is a adjustment on the starter that adjusts for when power is applied to the motor when the bendix teeth are at a certain depth. The button on top of a CJ3A starter rotates on threads. Out or rearward means the teeth engauge farther before the electrical contact energises. On a M38 starter there is a screw in the base of the electrical ring in the switch. That took me a while to find that one. It basically does the same thing. This is the early M38 type. Not sure on the later type. Take a look. Oilly

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 28, 2016 16:47:38 GMT -5

Moose - You are correct. An MB ring gear has 97 teeth. That's why I smashed it off the MB flywheel and replaced it myself with a supposed NOS 3A ring gear from QTM parts. Awwwww, yes....I see...you've been watching Schillers school of hard knocks bantam trailer videos. |

|

|

|

Post by Ryan_M on Mar 28, 2016 17:19:35 GMT -5

You put the ring gear on with the slight bevel on the teeth forward? If that is good, then there is a adjustment on the starter that adjusts for when power is applied to the motor when the bendix teeth are at a certain depth. The button on top of a CJ3A starter rotates on threads. Out or rearward means the teeth engauge farther before the electrical contact energises. On a M38 starter there is a screw in the base of the electrical ring in the switch. That took me a while to find that one. It basically does the same thing. This is the early M38 type. Not sure on the later type. Take a look. Oilly The ring gear teeth are not beveled at all. There is a bevel on the inside edge of the ring that was supposed to face forward (I think) and I remember making sure I had that right when I installed the ring gear. I found and adjusted the starter button in and out but it makes no difference in the grinding. The sound does not transfer nearly as well as I had hoped in this video but I'm posting it anyways. When then starter is turning it doesn't grind but makes a much raspier and metallic sound than normal. The second the engine starts to fire the starter grinds no matter how fast I take my foot of the plunger. It's much more pronounced in person. Just for kicks I measured the distance from the face of the starter to the face for the ring gear teeth on the installed set-up - roughly .0942". Measuring the old motor now sitting on the floor it was .0977". Pretty close. I'd love to know if I'd still have this same grinding if I swapped the old ring gear and flywheel onto this MB motor. Not too thrilled about having to pull the motor again to do it though. I removed the starter and reinstalled. No difference. Anybody see anything alarming?   And no matter what I do to this pic it still shows up here upside down....  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 28, 2016 17:26:45 GMT -5

Ryan, I have no idea how you would check, but my first car was a 67 Pontiac, when i needed to replace the starter I found a shim under one bolt.

I figured it was a factory fix and re-installed it with the new starter..never tried to start it without the shim..but figure it was there for an angle correction. good luck!

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 28, 2016 18:46:40 GMT -5

Watched your video. The bevel that I'm thinking about was on the 97 tooth ring gear I just installed in Bugsey. So, maybe the 124 tooth ring doesn't have a bevel. Anyway, I'd not pull the engine. Not one sign of rubbing or a mark on it. I think BD7's shim idea would be my next move. My Jeeps all make different sounds between them with the starter, and yours quite frankly cranks well. Just makes more noise than the other. It engauges and releases, so it can't be off much. I have a CJ3A starter that made a grinding noise, but it was coming from a bad bendix. Changed starters and no more noise. If that starter didn't make the noise in the old set up, then I doubt it's the bendix. Lucky you , another glitch to wonder about. Oilly

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 28, 2016 18:54:51 GMT -5

There should be a bevel ground into the face of the flywheel teeth as Sir Oilleaker mentioned earlier, not seeing that on yours. (Insert blue language of choice here) may be the issue!  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 28, 2016 18:56:32 GMT -5

Heading out to look at a flywheel, stand by!

|

|

|

|

Post by Ryan_M on Mar 28, 2016 19:08:02 GMT -5

Oilly - It sounds much worse in person. You don't see any wear on the ring gear because it's brand new with less than 10 starts a 5 minutes of run time. I guarantee it won't hold up that well though.

I looked at the MB ring gear and those teeth are heavily beveled. The ring gear teeth on the old 3A motor are very slightly beveled...the first noticeable difference between old and new. I need to research some more but I've found other references online to 3A ring gears not always being beveled. I may throw this question out on the 3A forum just to see what else shakes out.

When I have more time this week I'll see if I can swap the starter from my gray 3A just to try and pinpoint the exact culprit. Grrr....

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 28, 2016 19:41:58 GMT -5

Should there be a bushing in the bell housing where the end of the armature shaft fits? But no change there right? Same starter/bell housing combo? I've never seen a ring gear w/o some degree of bevel. |

|

|

|

Post by Ryan_M on Mar 28, 2016 19:48:26 GMT -5

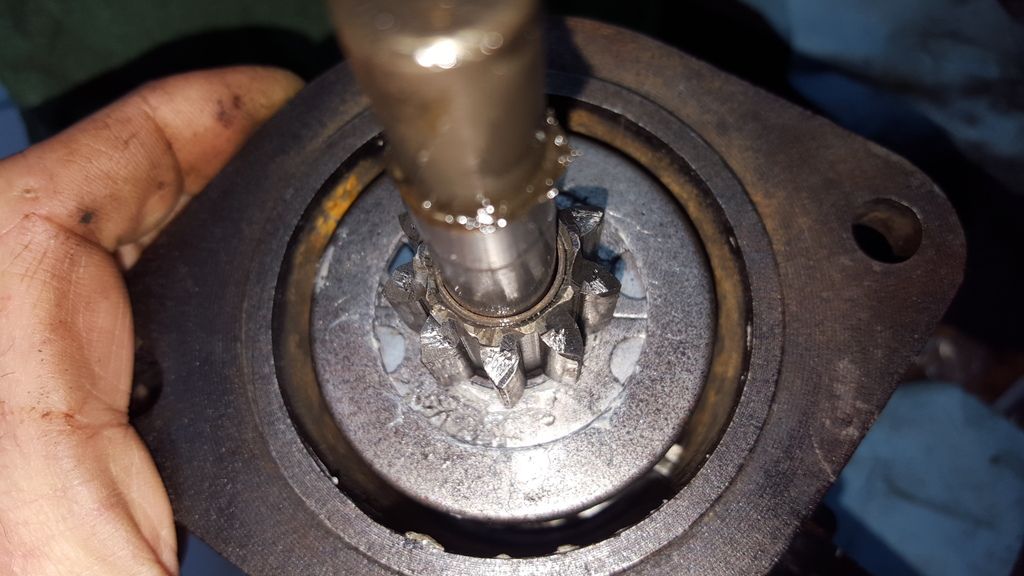

Should there be a bushing in the bell housing where the end of the armature shaft fits? But no change there right? Same starter/bell housing combo? I've never seen a ring gear w/o some degree of bevel. There is a bushing in there but you can't see it in that pic. I just scrounged up pics of the gray 3A when it was apart. No bevel on those teeth either. That makes me feel (a little) better. |

|

|

|

Post by Haines Garage on Mar 28, 2016 21:09:28 GMT -5

Is the bushing in the bell housing new?

|

|

|

|

Post by Haines Garage on Mar 28, 2016 21:13:00 GMT -5

The pic of your starter. The sleeve the gear slides onto seems really pitted. Does that matter?

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 28, 2016 21:15:07 GMT -5

I was sidetracked!, Anyway I removed a starter from an M38 engine in the garage and as Sir Ryan said a slight bevel, I also had a another flywheel I looked at and a slight bevel there as well, I would say there is a front and a back to the ring gear as the back side is squair, no bevel..

|

|

|

|

Post by Ryan_M on Mar 29, 2016 3:23:32 GMT -5

Haines - I did not replace the bellhousing bushing. I probably should have but did not. Seemed ok. The starter shaft looks pitted in the pic but it isn't - that's just grease and it wiped right off.

Cap'n - Thanks for the effort. Interesting that the M38 teeth are beveled. Because I am insane and this stuff drives me crazy, I was up an hour-and-a-half ago and pulled the starter off the gray 3A. Those flywheel teeth are definitely not beveled. A little worn on one side, yes, but originally straight cut for sure.

I swapped the starters on both Jeeps and now sit here waiting for the rest of the house to wake up before I test fire each of them. Very curious to see what happens. With a little luck the grinding follows the red 3A's starter....

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 29, 2016 3:54:57 GMT -5

Coffee!

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 29, 2016 4:23:26 GMT -5

I'll admit up front that I've got nothing.

Could it be the ghost of the WW2 ring gear that you mutiliated shrieking at you?

Or

Has anyone else ever used a brand new NOS ring gear? Maybe this is what they do when they have such sharp edges.

Was it easy or hard to remove the old and replace it with the new? Can the new one go on and not be square? I've never done it before.

|

|

|

|

Post by Ryan_M on Mar 29, 2016 4:28:27 GMT -5

I had never replaced a ring gear before either but a quick YouTube education taught me enough to give it a try. It really was pretty simple and I'm certain it went on square. I can't imagine they are supposed to grind for any period of time when new. Maybe, but geez, would have bene tough to sell a brandy new Jeep off the lot if they all sounded like this when a prospective buyer fired one up for the first time.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 29, 2016 5:45:17 GMT -5

Does the starter fit the motor plate well and sit flat? Just wondering if there is a difference between the WW2 one and CJ3A one. Might be cocking the starter? It obviously has to go in the bushing or it wouldn't work at all. Are you using the same motor plate that was on the 3A or the WW2 one? Something has changed during the swap. Oilly

|

|

|

|

Post by Ryan_M on Mar 29, 2016 5:53:00 GMT -5

Does the starter fit the motor plate well and sit flat? Just wondering if there is a difference between the WW2 one and CJ3A one. Might be cocking the starter? It obviously has to go in the bushing or it wouldn't work at all. Are you using the same motor plate that was on the 3A or the WW2 one? Something has changed during the swap. Oilly I'm using the MB motor plate. Seems to fit. I swapped starters with the gray 3A and the problem is not with the starter. Regardless of what starter is where the gray Jeep doesn't grind and this red one does. Still doesn't solve my problem but at least eliminates the starter itself as a culprit. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Mar 29, 2016 15:54:19 GMT -5

So, the starter slides right in and you can move the starter some in order to put both bolts in? Is there a noticeable difference in the motor plates between the two? I guess what I'm getting at is how the nose of the starter fits in the motor plate hole. Wondering if it hits anything that changes how it centers in the hole. I see a small step to the starter , and a shelf just inside the motor plate which is the bell. Possible pressure as you tighten the starter up. Oilly

|

|

|

|

Post by Ryan_M on Mar 30, 2016 7:11:29 GMT -5

I think everything is clear on alignment. Step/shelf seem to mesh as they should without binding or having any other undue stress on them.

Engine plate thickness on the gray 3A, the old red 3A motor, and the new MB motor are all the same: 0.102"

The new ring gear teeth themselves are slightly smaller in front to back depth. The new teeth on the MB flywheel are 0.34" and the gray 3A and old red 3A teeth measure 0.378".

I am out of time this morning but I have a couple other things I want to rule out. I'd like to see what is happening at the starter when I push the starter pedal. Since I only have one set of eyes I will set up a camera to do this. Is there a chance the starter pushrod is fetching up on something? The bottom of the coil maybe? That might be limiting the distance of the throw. Hopefully I get home early enough tonight to mess around some more.

|

|

|

|

Post by Ryan_M on Mar 30, 2016 20:19:30 GMT -5

Still running in circles. I confirmed that the starter push rod pedal is not binding on anything. Next, I swapped push rod pedals with the gray 3A. There's no doubt the bend in the pedal and adjustment of the starter button are important but no matter what I did I couldn't get it to solve my problem. I even swapped batteries just to rule that out. Below are pics of the gray 3A starter that I tried on the red one. This starter was just overhauled a couple weeks ago and has started the gray 3A maybe three times since then. The teeth were dressed smooth during the overhaul. You can see where they've been chewed on, presumably now from the red 3A test.    The "grinding" still seems to be the worst when the engine starts to fire - as if the starter drive doesn't disengage as fast as it should. Either way, I'm not in any big hurry to pull the motor and change flywheels especially since I do not know for certain that would even solve the problem (although I think it would...). I might as well just run it. Worst case is I destroy the ring gear that I was going to have to change anyways and beat up the old starter which could probably use an overhaul. Best case is the gears wear justa bit and learn to mesh a little more quietly. Besides, I have a rebuilt trans and TC installed that I haven't even tested yet. No sense in pulling the motor until I know whether or not the rest of the drivetrain should need to come back out. New and much needed clutch cable arriving later this week so we should be mobile again. Nothing like a full first-time test drive to discover more catasrophes.... |

|