Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 5, 2014 12:11:44 GMT -5

What is the current opinion of these bastages? Who has got the quality ones in stock?

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 5, 2014 18:42:57 GMT -5

The last ones I used where neoprene Fel-pro models, it still drips.

Although, I could very well did something wrong when installing it.

If you want, I ll dig out the part number when I get home in the morning.

I'm sure somebody else will chime in with more helpful information...

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 5, 2014 19:04:50 GMT -5

Midwest military  Lee  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 8, 2014 6:55:08 GMT -5

John B stopped those for a while, did he start sellin them again? Wes Knettles posted a download about checking your crankshaft journal size for being the wrong size, and that you need to get it polished or ground to within specs. If that seal journal is off or rough, you are better off with the rope seal. I use a rope in mine to protect against the seal faiure and engine getting messed up with all the snarf that gets into the oilling circuit. A drip or small spot is quite normal to me. After all, they don't call me Oilleaker for nothing!

|

|

|

|

Post by Moseying Moose on Aug 8, 2014 9:52:26 GMT -5

If my memory is as sharp as my wit (haha  ), it was being sized to 40 over on the mains (the crank, that is). I ordered the engine overhaul gasket set from Ron and I think it comes with the rope seals. This should be fun. Based on my GPW, just call me Jr., Sir Leaker. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 8, 2014 10:01:01 GMT -5

Oil brothers huh?

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 8, 2014 10:42:29 GMT -5

Thicker (and slicker!) than blood brothers!

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 8, 2014 10:48:56 GMT -5

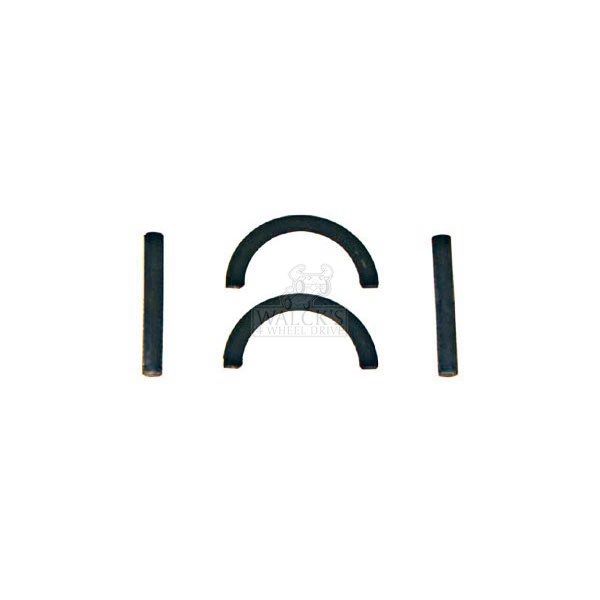

Rear main eBayWhat about these? Would they still work being this old? Seems like it would be easier than playing with the ropes. I've heard the rope seals can be quite finicky. On the flip side, I've read some dodgy things about this seller. Thought? I know all of you have them.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 9, 2014 7:30:45 GMT -5

Victor made a bunch of those that were bad. Some guys blew their engine up because that seal was too tight and burned up from friction. The chunks got into the oil and plugged things up. No oil to the bearings in places. Then, bang! bye bye engine. The crankshaft should turn easily by hand when assembling and plastigauging things. If you try a rubber rear main, it should still turn by hand with a very slight difference. If it turns hard or locks it up so you can't turn it by hand, stop right there. Some machine shops put them in since they came in the kit, and then ate the rebuild. Imagine all the finger pointing and blaming going on that caused the engine failure! The rope seal will leak some in time, but I've never had a failure. Oil is cheap in comparison. Oilseal leaker

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Sept 22, 2014 21:41:09 GMT -5

I just installed this one today. Talked to Carl at Walcks and he assured me they have had no problems with these. I hope that is the case!  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Sept 27, 2014 14:12:18 GMT -5

Low range...did you use one of the old school rope seals?

There is a lot of advice online for installing these things. Anyone want to offer up their two cents?

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Sept 29, 2014 17:59:03 GMT -5

First off, if you use a neoprene seal, you fit the main bearings and see if the crank turns easily by hand. Then pull the crank and install the seal. If you can still turn the crank fairly easily, you are good. If it's hard--------back off and use the rope seal. I've used them in all my motors. The plan is to leave one side a little long after you roll it into it's slot with a socket to make sure it's at bottom. I cut the rope with very high quality sewing sissors. Not even a razor blade will work. the other side a little short, and then the same with the cap. The overlap is supposed to seal the crack. You can work excess into the groove with a dull wedge or screwdriver. I've had excellent results. I also put permatex on the rubber dowels that go on both sides of the rear main. They should stick out about 1/4 inch and crush with the oil pan installation. Also; the seal surface on the crankshaft should be polished when they machine the crank. The horror stories of the lip seal galling and putting rubber into the oil galleries and subsequent engine failure due to blocked oil passages and then a locked blown engine make me say all of this. They don't call me Oilleaker for nothing! Got it? Oilly

|

|

|

|

Post by Haines Garage on Sept 29, 2014 18:08:42 GMT -5

Yeaaaah...

What he said!!!

Thought everyone knew that!!!

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Sept 29, 2014 18:38:10 GMT -5

I'm rope sealing it. Glad you mentioned the scissors, oily....I thought I had 1/2 dozen really dull razor blades! I used the scissors, too.

|

|

|

|

Post by Haines Garage on Sept 29, 2014 18:46:39 GMT -5

Ummmmm.

I was told that you were not allowed to play with scissors.

I am telling!!!!!

|

|

|

|

Post by rqualls on Oct 3, 2014 4:45:39 GMT -5

Maybe if I put 38s on the back, and 6.00x16s on the front it won't leak  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Oct 3, 2014 7:13:47 GMT -5

Maybe if I put 38s on the back, and 6.00x16s on the front it won't leak  I'd love to see that! ...but not on my jeep! |

|