|

|

Post by Ryan_M on Dec 8, 2013 18:29:10 GMT -5

I installed a bellcrank repair kit and am having a tough time getting the bellcrank back on my M38. The inner bearing sleeve hits a same diameter piece coming out of the bottom of the frame mount. When I fully install and torque the nut on the shaft the bellcrank binds and is impossible to move. If I were to drive the bellcrank inner bearing sleeve down it would no longer be flush at the bottom and cause a problem there too. I am cross-eyed from scouring the web for a detailed bell crank install procedure and exact fitment of components. Can someone point me in the right direction or tell what's wrong from the pics? The rubber dust cap has intentionally been left off here.   |

|

|

|

Post by Haines Garage on Dec 8, 2013 19:54:15 GMT -5

Ryan, I know very little about the M38. The 2a has a pin and nut like this.  From your pics, what holds the bellcrank in place? Is it a bolt that hold the bellcrank on? |

|

|

|

Post by Haines Garage on Dec 8, 2013 20:00:20 GMT -5

I also see pics at E willys... Do you have the brass washers I see in there photo? I googeled M38Bellcrank..

I am willing to help, best I can...

That's what this club is about...

Even if you don't know, sometimes, talking through sparks an idea!

|

|

|

|

Post by Ryan_M on Dec 8, 2013 20:32:40 GMT -5

2A bellcrank is a different animal. As usual, I posted this in a few different forums. I'm making some progress over on the 3A page but still would like a pic of the M38 bellcrank bracket if anyone has one. Specifically the bottom of the bracket with the bellcrank removed...or better yet, a detailed exploded parts diagram.

|

|

|

|

Post by Haines Garage on Dec 8, 2013 20:46:37 GMT -5

Have you tried the site Oileaker listed on the bottom of the pages here?

I see some stuff on the 503.....

I am probably searching the same as you. This is valuable info.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 8, 2013 20:55:12 GMT -5

Perhaps your bushing is to long, did you compare the length of the old/new prior to installing the new?, just a thought. Lee  |

|

|

|

Post by Ryan_M on Dec 8, 2013 21:10:43 GMT -5

Old and new bushings are the same size. The bolts, I realized, are different. I put it all back together with the old bolt and it functions properly. I am now trying to determine if that "sleeve" bit protruding from the bottom of the bell crank mounting bracket is supposed to be there or not. On a 3A, it's flush. Not sure if M38's are different or if this is the work of a previous Bubba. I'd like to know for sure before I fire up the grinding wheel.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 8, 2013 21:19:00 GMT -5

As Haines has suggested, I would go to the Willys M jeep site and inquire there, Wes there knows everything M-38. Lee  |

|

|

|

Post by Haines Garage on Dec 9, 2013 15:24:52 GMT -5

Ryan, how did this work out....  ?? |

|

|

|

Post by Ryan_M on Dec 9, 2013 15:47:46 GMT -5

|

|

|

|

Post by Haines Garage on Dec 10, 2013 15:54:05 GMT -5

Thats great ! When done, could you show that here in your thread...Help someone out in the future perhaps you will.....

|

|

|

|

Post by Ryan_M on Dec 11, 2013 20:00:18 GMT -5

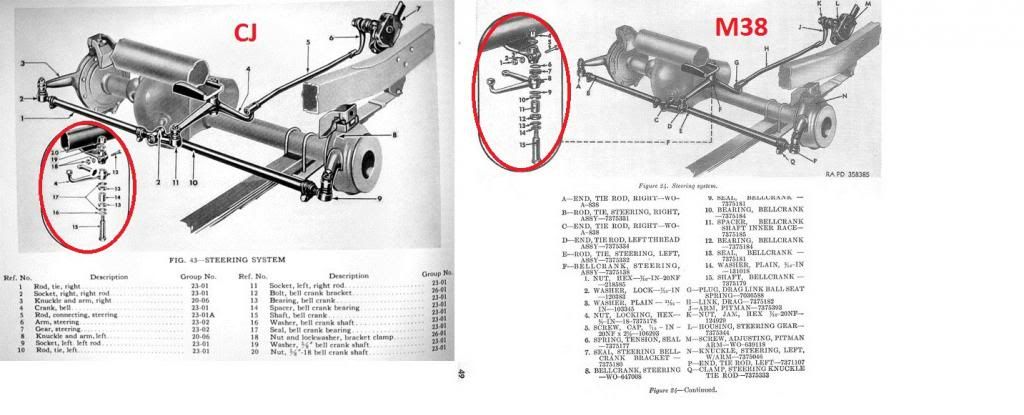

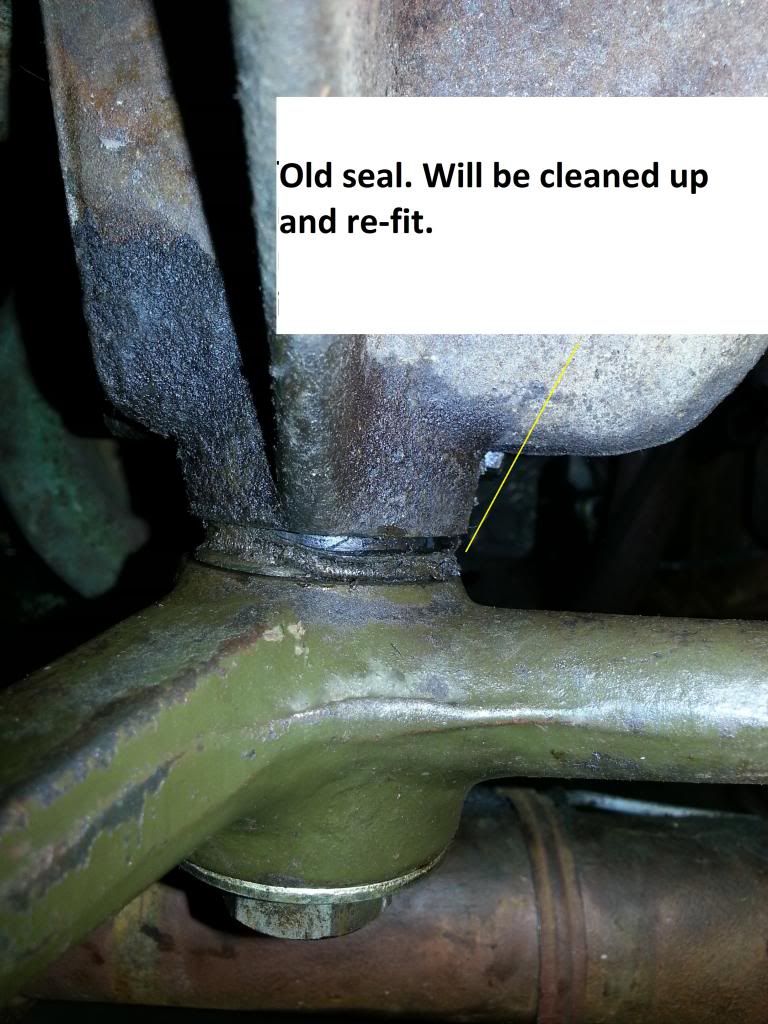

Ok, for those of you who ever face this problem, reading this thread will save you a week of sleuthing around the 'net looking for answers. The M38 frame mounted bellcrank bracket is nearly identical to the 3A bellcrank bracket except for a small collar that protrudes from the bottom of the M38 bracket, visible here:  That's not necesarily a big deal but many of the bellcrank rebuild kits available are sold as being compatible across a wide range of models - late CJ2A, CJ3A, CJ3B, CJ5, CJ6, DJ, FC 150, M38 and M38A1. I can't speak for all of them but I know the 3A and M38's are definitely not the same. Since the M38 has that collar, the bellcrank shaft (#15 in both exploded parts diagrams below) is different. In this picture, you can see the one that came out of my M38 and the new one included with the kit   The lengths and proportions are just different enough that installing the new one and torquing it down causes the bellcrank to bind very tightly. I ended up reusing the old shaft along with new bellcrank bearings, bearing seals, and inner race which all fit and functioned as expected. Absent from the new kit were #6 "SPRING, TENSION, SEAL" and #7 "SEAL, STEERING BELLCRANK BRACKET" as pictured on the M38 parts diagram. Luckily, my old seal is reasonably salvageable and I'll be able to clean and reuse it. This seal is probably not critical unless you expect for submerge the bell crank. M38's were designed for fording and this is one of those refinements.  So this is what I've learned this week. If I'm wrong on any of it feel free to correct me or add to the info. |

|